Introduction

In common with any complex system our railways must balance multiple tensions between competing requirements and as the social, economic and political environment alters different tensions will come to the fore. One such tension exists between the requirement for more on-train passenger-carrying capacity – seated and total – and the expectations of passengers upon the journey environment quality and value for money.

Competing demands

With demand for rail travel increasing, especially commuting, and constraints on both network capacity and investment in rolling stock, operators need to accommodate more passengers on each train. This is especially apparent during peak periods when demand is highest. Indeed recent franchise specifications have incentivised ever-higher seated and total passenger capacities. The drive for more capacity has seen seating densities increase generally and space allocated to First Class travel being reduced or removed altogether.

At the same time, as passengers spend more of their money and their time on their train journeys they tend to become less tolerant of standing in a crush or of not getting a seat in the first place. Longer-distance commuters particularly expect to be able to travel in comfort and make productive use of the journey time – as do business and leisure travellers.

How do we balance what passengers really want – useful journey time or just minimised journey time? A comfortable environment, or just a seat? – or perhaps just to be able to get onto the train at all? Of course all of these wants are required by different passengers at different times.

Challenge

Any one train configuration may well have to fulfil different passenger requirements – during a single daily diagram, during a single journey leg, or more likely simultaneously. The train builder / owner is given the challenge of deriving a configuration that achieves the best compromise between these competing requirements – which for broad simplicity we will call ‘capacity’ and ‘comfort’.

Door Configurations

At a simple level the configuration aligned towards comfort generally has doors at the ends of the vehicle leaving a large saloon section between them for comfortable seating, in the middle of the vehicle where the ride is better, and away from the doors and associated disturbance from draughts and commotion as passengers board and alight. Interior doors often provide further insulation from the door and vestibule areas. The long narrow aisle, as well as the interior doors, tends in all but the most overcrowded scenarios to discourage excess standing passengers from moving down the aisle into the saloon and upsetting the comfort environment. Any tables provided for comfort will necessarily displace capacity.

The configuration aligned towards capacity generally has doors at the ‘one third two thirds’ positions, where wide dual-leaf doors and large vestibules can facilitate the rapid boarding and alighting of large volumes of passengers within a reasonable station dwell time, in a way that the typical end-doors configuration (with narrower doors and smaller vestibules) cannot. The large vestibule footprint, which generally extends as a circulation area into the immediate saloon without interior doors, helps to funnel standing passengers into the wide aisle between the seats and encourage them to move down and utilise this additional standing space. Any comfort environment that isn’t already spoiled by close proximity to the draughts and commotion of the vestibules and doors will tend to be upset by the press of standing passengers.

The conflict

Clearly there are deviations and blends between these extremes and there are many other factors that come into play in the provision of capacity and comfort, and in the behaviours of passengers. However, the conflict within our train configuration between meeting both the capacity and comfort requirements becomes apparent. The capacity (one third two thirds doors) solution sacrifices on comfort, permanently – even when lightly loaded. The comfort (end-doors) solution sacrifices on capacity, permanently – during peak periods it is difficult within station dwell times to accommodate the boarding and alighting passenger exchanges let alone persuade standing passengers to move down into surplus aisle space, further away from the doors (and their intended exit).

Is there a potential solution to provide maximum capacity, but protect the ‘comfort’ environment or at least a portion of it?

The need

The requirement for capacity is unlikely to recede, albeit recent quarters have seen some nuances in the trends with falls in the number of journeys made in 2017-18 Q2 using season tickets while journeys made on non-season tickets continued to grow and journeys made on anytime/peak tickets reached a record 101m in 2017-18 Q2 . So our solution needs to maximise capacity. This suggests wide dual-leaf doors and large vestibules; circulation areas leading into wide aisles and areas of high density seating.

The requirement for comfort suggests a saloon section (with necessary comfort features such as tables) that enjoys a degree of isolation from the doors and vestibules and some protection from crowding.

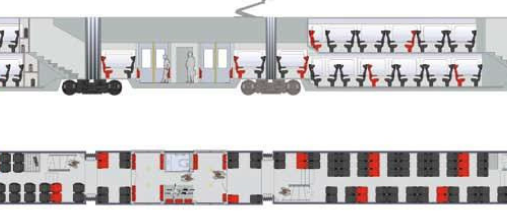

Mechanisms exist to manage demand – which would be a means to protect comfort. Eurostar avoids excess (standing) passengers through employing an airline-style booking-only regime on its services, but this would constrain our capacity aspiration. Class segregation arrangements that reserve capacity for First Class in the face of excess (Standard Class) demand are inflexible – again constraining our capacity. Therefore any protection from crowding would need to be inherent in the layout without wasting precious capacity. Rolling stock manufacturers have taken steps to meet these dual requirements with a combined layout. Bombardier’s OMNEO double-deck product is one such example (see Figure 1). In the OMNEO a separate short articulated vehicle section with multiple doors and vestibules provides a circulation space to assist in handling the boarding and alighting during limited dwell times as well as excess standing passengers, whilst seated accommodation is segregated in adjacent vehicle sections.

Figure 1 Bombardier OMNEO combined layoutA solution for the UK could adopt this articulated formation, albeit constrained to single-deck configuration, whilst a potential combined layout for regular UK-style non-articulated single-deck vehicle formations is offered in Figure 2.

With the exception of a limited portion configured for comfort the whole layout is optimised for capacity. The key aspect is segregating the interior layout; placing the circulation areas and doors next to each other at the ends of the vehicle where ride and noise levels are already poor and placing the comfort area in the middle of the vehicle (where ride and noise levels are best) – and as far away from the circulation areas as practicable, and further separated by a high capacity seating area and sets of interior doors. The dual-leaf doors and connected circulation areas will accommodate boarding and alighting passenger exchanges and the demand for capacity, whilst graduated separation will deter excess standing passengers from spilling through the high density seating area into the comfort area in all but the most overcrowded conditions – an inherent segregation.

Figure 2 Wide end doors and a ‘graduated’ interior layoutBenefits

A number of potential benefits with this interior configuration concept emerge:

- Capacity is maximised in line with the best ‘one third two thirds’ layouts (but for a small part of the saloon being optimised for comfort);

- Dwell time performance in crowded conditions is potentially improved both by the dual-leaf doors and large circulation areas connected through an open wide gangway and by fewer ‘traps’ from which passengers must push through aisles full of standing passengers in order to reach the exit doors (typically the vehicle ends on ‘one third two thirds’ layouts);

- The comfort area has the best attributes of a good end-doors vehicle layout and these can continue to be enjoyed whilst the normal draughts and commotion of door activity takes place, and as the train fills up. It should be acknowledged that this works well on the way to London (or other commuting centre) – the passengers with the longest trip board first and head for the most comfortable seating. On the way out of London it is much less effective. Unless the long distance commuters can arrive early and be permitted to board ahead of the rush towards train departure time then everyone heads for the comfy seats and then causes a disturbance if they alight before the train becomes lightly loaded and even long distance commuters do not typically relocate to better seats once they become available;

- Vehicle design is simpler since the door apertures are located in an area of lower carbody stress. Furthermore, doors located nearer to the bogies enable stepping distances to the platforms to be achieved more easily.